This is another Funline pen kit from Penn State Industries. The blank is one of their blue and white Funline Crush blanks. The kit is satin gold.

This is another Funline pen kit from Penn State Industries. The blank is one of their blue and white Funline Crush blanks. The kit is satin gold.

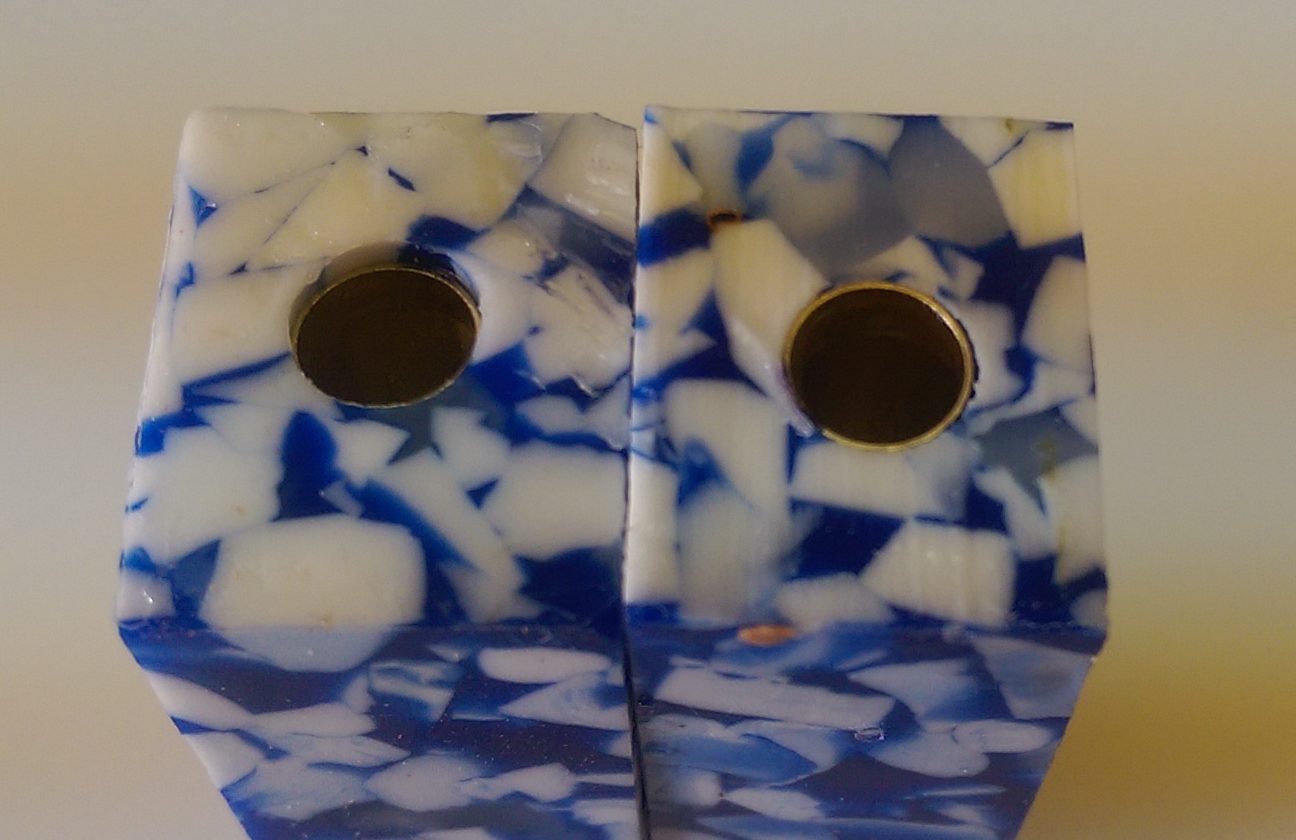

I’ll be really good at pens as long as I learn from my mistakes. This funline pen turned out very nice but I had a few concerns along the way. To reduce blowout I drilled one side then flipped the blank over to finish off from the other end. Since the blank was rectangular the holes didn’t line up perfectly. I ended up with a less than perfect fit for the pen tube. You’ll notice the gap between the tube and blank on the right hand piece. I filled the gap with CA glue and didn’t have any problems turning it but I am concerned about it’s long term integrity.

Once the CA cured I proceeded to square up the blanks. I’ve noticed that my pen mill is causing damage to the tube interiors, as you can see in the second photo. This brass fuzz jammed up on the mandrel and it took considerable time and all the strength I had to remove it without damage.

Once the CA cured I proceeded to square up the blanks. I’ve noticed that my pen mill is causing damage to the tube interiors, as you can see in the second photo. This brass fuzz jammed up on the mandrel and it took considerable time and all the strength I had to remove it without damage.

Here the pen is roughed down and ready for sanding. There are several translucent pieces in the casting and you can see the tube through them. I know I need to paint the tubes to avoid this, but I haven’t tried it yet.

Wet sanding doesn’t generate much dust so I’ve removed the dust collector and put down some towels to protect the bed of my lathe. I used conventional cloth backed sandpapers in 240, 320, 400, and 600 grits before switching to micromesh pads. I went through the whole micromesh series up to 12000. Then buffed the pen in three steps with Tripoli, White Diamond, and finished with Carnuba wax.

Pen Turning Lessons Learned

I reached out to RJB Woodturner to see if this was a common problem and find out how to avoid it. It was really great to get a quick reply and some confirmation that it wasn’t necessarily me. He let me know that the pen mill is an aggressive tool and that what I was seeing is common. He said that a disk sander and jig can be used as an alternative. I watched his three-part video series on sanding blanks with a disk sander. Based on his videos, I’m going to put together a similar setup using a 3″ faceplate and a punch in my collet chuck.