Turned my second pen this morning. This time it took me about an hour and a half from start the finish; about half the time of my first. I sharpened my tools before I started and again about half way through. Sharpening made a noticeable improvement in cutting speed. There was also less complaint from the lathe with the sharper tools. While turning the first pen I noticed some vibration or maybe chatter from the blank towards the tailstock side. I’m assuming it was from excessive force while cutting that end. I did not experience the same problem this time.

Sanding went well. I used 450 and 600 grit conventional sandpaper before going through the Micromesh series. I finished up the pen with the three step buffing system from Penn State.

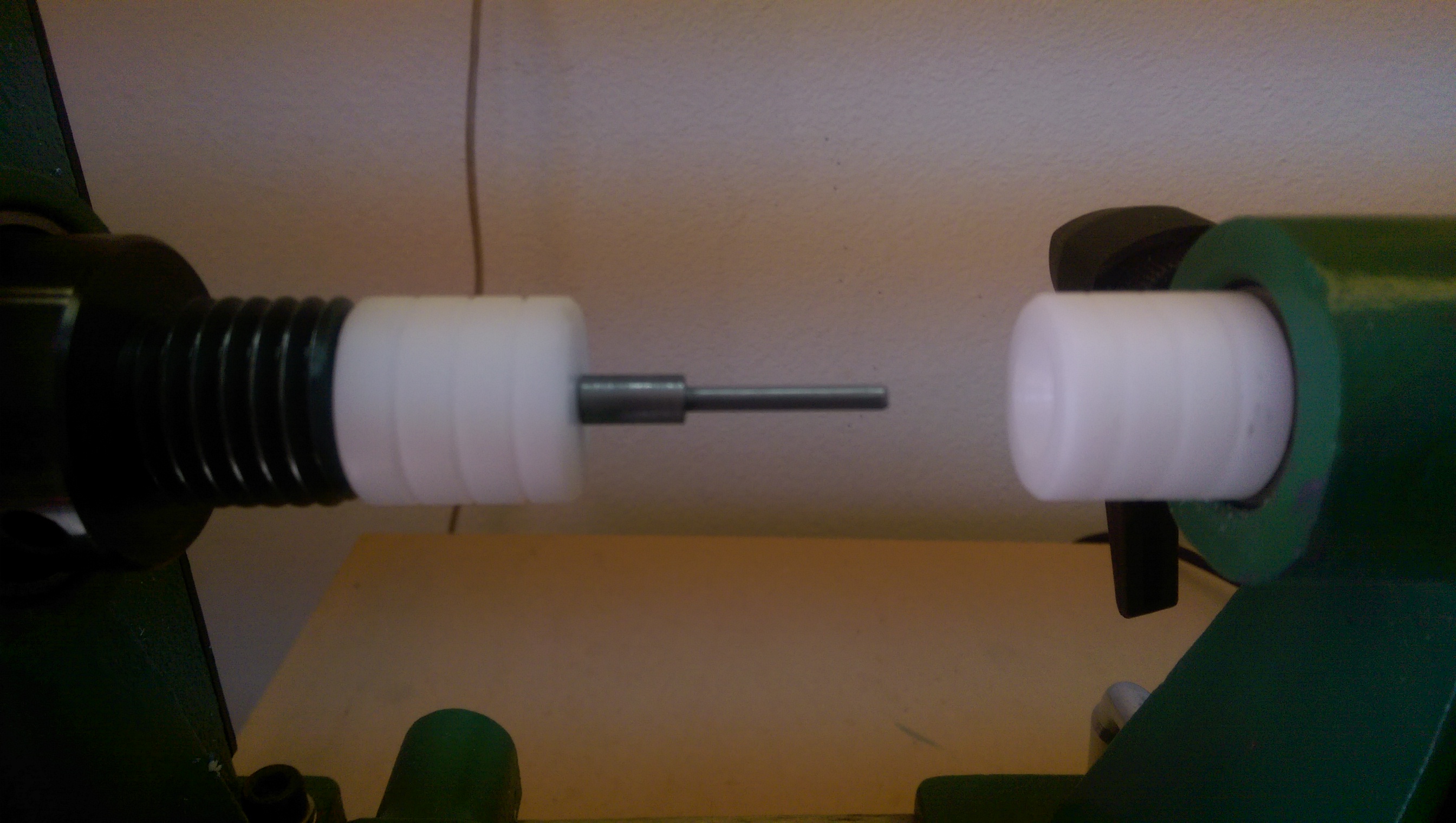

Assembly was a snap with the Artisan Pen-Ultimate Assembly tool from Craft Supplies USA. I like not having a large press around when it’s not always needed. I wish the the dish was a little shallower on the assembly tool. It presses against the pen clip a little when pressing the end cap on these funline pens. This hasn’t caused any trouble, it’s just something I’ll remain aware of. I’d prefer the only contact to be on the end cap.

Dished head of pen press

Pen Turning Lessons Learned

- If I flip the cap side blank around and remove the center pin from the assembly tool I can press the end cap on without pushing against the clip.

- Sharpening the tools throughout the process really reduces the pressure required, which reduces fatigue and the chance of an accident.

- My lathe is too high. My workbench is at an excellent height for me to work on but with the added distance to the lathe spindle it’s actually too high to comfortable work on. I’ll have to build a separate stand for it in the near future.